Soldes ®4483Lot de 4 Chaises de jardin Chaises de metteur en scène |Fauteuil de Jardin| Fauteuil Relax Chaises Camping Acacia massif - Cdiscount Jardin

Soldes ®6752Lot de 2 Chaises de jardin Fauteuils de Jardin Chaises de Camping ErgonomiqueRésine tressée Gris - Cdiscount Jardin

Soldes ®8294Lot de 3 Chaises de jardin|Fauteuil de Jardin| Fauteuil Relax Chaise d'extérieur avec coussins vert 3 pcs Bois de teck m - Cdiscount Jardin

Soldes - Mobilier FR92349M 2 x Chaise de jardin avec coussins Fauteuil de Jardin , Chaise d'extérieur Résine tressée Gris foncé - Cdiscount Jardin

Soldes ®7595Lot de 2 Chaises de jardin pliables Ergonomique|Fauteuil de Jardin| Fauteuil Relax Chaise d'extérieur avec coussins Bois - Cdiscount Jardin

13060|Jill's•) SOLDES CHIC Chaise pivotante de bureau BEAU - Fauteuil de Bureau, pour Ordinateur, Gamer Gris foncé Velours - Cdiscount Maison

31133|Jill's•) SOLDES CHIC Fauteuil relax demassage électrique BEAU - Vibration Fauteuil inclinable demassage Noir Similicuir - Cdiscount Maison

Soldes ®1799Lot de 3 Chaises pliables de jardin|Fauteuil de Jardin| Fauteuil Relax Chaise d'extérieur avec coussins Bois d'acacia - Cdiscount Jardin

Soldes ®6248Lot de 2 Chaises de jardin pliables Ergonomique|Fauteuil de Jardin| Fauteuil Relax Chaise d'extérieur avec coussins Bois - Cdiscount Jardin

Soldes ®3558Lot de 4 Chaises de jardin Chaises de metteur en scène |Fauteuil de Jardin| Fauteuil Relax Chaises Camping Acacia massif - Cdiscount Jardin

Soldes ®2199Lot de 4 Chaises de jardin Chaises de metteur en scène |Fauteuil de Jardin| Fauteuil Relax Chaises Camping Gris Acacia - Cdiscount Jardin

Soldes ®1644Chaise de jardin Chaise pliable de metteur en scène |Fauteuil de Jardin| Fauteuil Relax Chaises Camping Bois de teck sol - Cdiscount Jardin

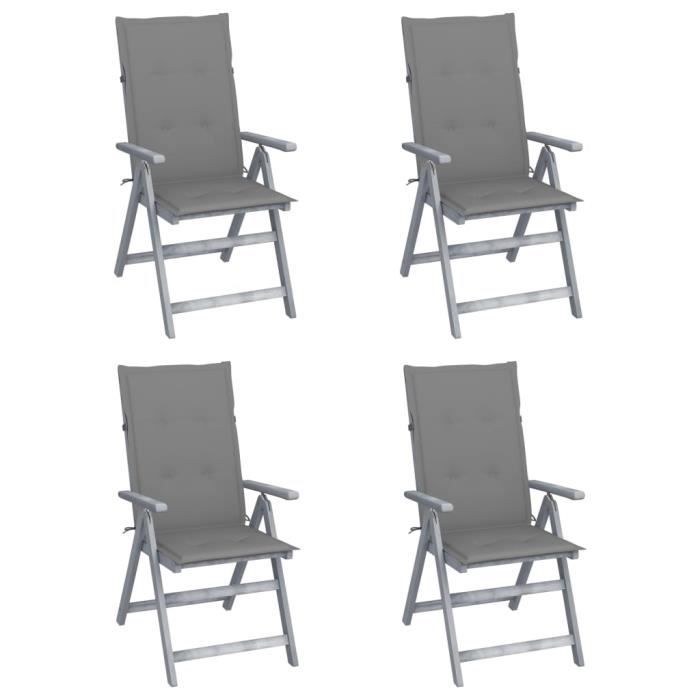

Soldes ®8328Lot de 4 Chaises inclinables de jardin |Fauteuil de Jardin| Fauteuil Relax Chaises Camping avec coussins Bois d'acacia - Cdiscount Jardin

73940|Jill's•) SOLDES CHIC Fauteuil relax demassage électrique BEAU - Vibration Fauteuil demassage inclinable Vert foncé Tissu - Cdiscount Maison

46330|Jill's•) SOLDES CHIC Fauteuil relax BEAU - Fauteuil de Bureau, pour Ordinateur, Gamer pivotante Vert Similicuir - Cdiscount Maison

Soldes ®5263Lot de 4 Chaises de jardin Chaises de metteur en scène |Fauteuil de Jardin| Fauteuil Relax Chaises Camping Gris Acacia - Cdiscount Jardin

Soldes ®9433Lot de 2 Chaises de jardin|Fauteuil de Jardin| Fauteuil Relax Chaise d'extérieur avec coussins vert Bois de teck massif - Cdiscount Jardin

Soldes - Mobilier FR49962M Lot de 3 Fauteuil de Jardin , Chaise d'extérieur Chaise de bistro, avec coussins Résine tressée Marron - Cdiscount Jardin