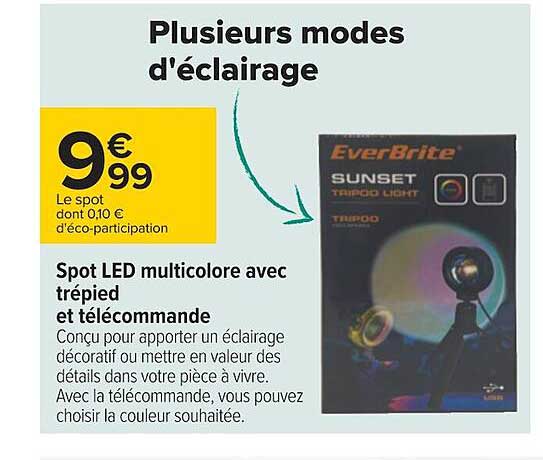

/product/24/161611/1.jpg?1932)

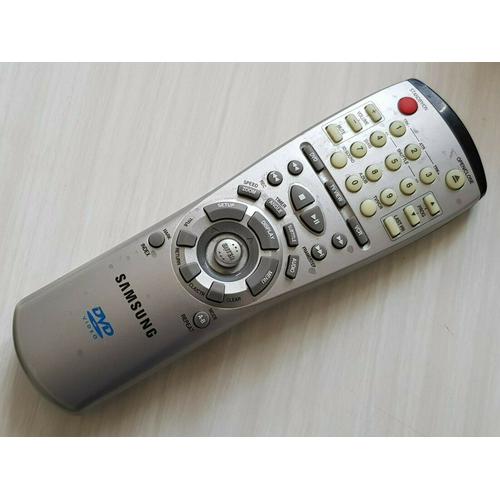

Samsung Télécommande TV pour Samsung TV Universal Tous les modèles Samsung LCD LED HD TV 3D Smart TV - Prix pas cher | Jumia SN

Telecommande Samsung AA59-00773A RMCTPF 2AP1 Samsung TV Télécommande AA59-00776A AA59-00778A | Rakuten

Télécommande Pour Aspirateur Robotique, Pour Samsung Vr7000m, Dj96-00201f/mg, Exp-20w-vg, Usa-2 - Télécommande - AliExpress

Pomme Store - Carrefour la Marsa Réparation iPhone ,Samsung ,Huawei , Batterie , connecteur de charge Soft et Hard #Ouvert de 8h a 19h 30 Tel : 20 294 610 | Facebook

Télécommande Pour Aspirateur Robotique, Pour Samsung Vr7000m, Dj96-00201f/mg, Exp-20w-vg, Usa-2 - Télécommande - AliExpress

![Temium REMPLACEMENT (SAMSUNG) | 23 avis sur Darty [4,7/5] Temium REMPLACEMENT (SAMSUNG) | 23 avis sur Darty [4,7/5]](https://image.darty.com/accessoires/accessoire_pour_televiseur/telecommande/temium_telec_samsung_d1906124654749A_174256612.jpeg)